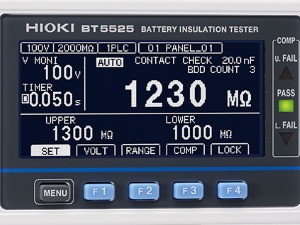

Prevents latent defective battery leakage that can cause fires. Battery insulation tester BT5525 Released

The Battery insulation tester BT5525 is often used in production lines for LIB (lithium-ion battery) battery cells. It is a device to detect insulation defects that cause battery ignition or reduce longevity. Until now, it has been difficult to detect latent defects in battery cells, such as the presence of metallic foreign matter or small short circuits. The BT5525 solves these problems by introducing new functions and improving measurement performance.

The insulation resistance test checks the hardness of electric current flow. The insulation resistance value is confirmed by applying a DC voltage to the measured object. If a battery cell is damaged or there is a work process error, the insulation resistance will be low, and the battery cell will be excluded as defective in the production line inspection. However, if metallic foreign matter (small foreign matter such as electrode fragments) is present in the manufacturing process, the insulation resistance may not drop immediately and cannot be detected. Undetected contaminants are latent defects that can cause degradation and internal short circuits when the finished battery is in use for an extended period of time. It can even be a potential fire hazard.

The Battery insulation tester BT5525 reliably and quickly measures insulation resistance in battery cell production lines. Detecting latent defects contributes to improving LIB safety and assuring quality (more info).