Hioki to Launch Three Battery Quality Testers in 2022 in Drive to Eliminate Battery Fires

Hioki is pleased to announce that in 2022 it will launch three new measuring instruments designed to detect latent defects in quality inspections on battery production lines. The company’s goal is to increase the safety of lithium-ion batteries, for which demand is growing worldwide.

Inside an LiB, the positive and negative electrode sides of the battery are filled with different electrolytes and insulated by a separator. Contamination with iron powder or the formation of burrs during the manufacturing process can gradually damage the separator, creating minuscule insulation defects where a short-circuit current can flow, generating heat. If the separator tears, a large current will flow, creating heat that exceeds design parameters. The resulting thermal runaway state could cause a fire by igniting the electrolyte.

The materials that make up an LiB are welded together with metal to facilitate the flow of current. Poor-quality welds have a higher resistance component that impedes current flows, resulting in heat loss. Heat loss not only reduces the battery’s thermal efficiency, but also impacts safety due to the potential of heat to lead to degradation and eventual failure. Because the welds in LiBs used in electric vehicles carry large currents during rapid charging and while driving, even a minuscule weld defect can cause extreme heating and fire.

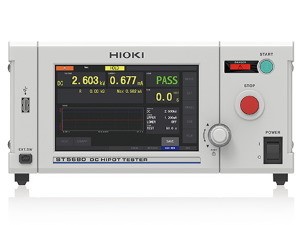

To address these risks, Hioki will make it possible to produce highly safe batteries by launching instruments capable of detecting the causes of defects that can lead to fires (more info).