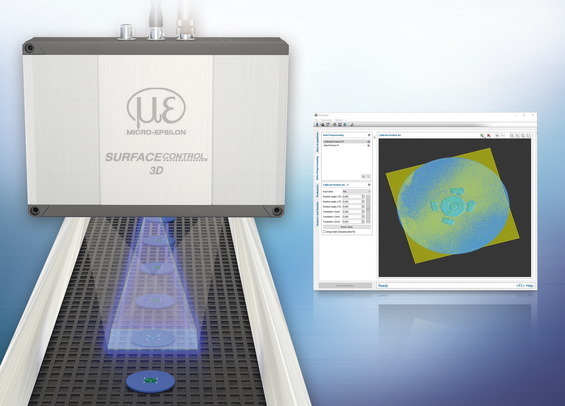

3D Inspection of unpopulated PCBs

For fully automated inline inspection of unpopulated PCBs, 3D snapshot sensors from Micro-Epsilon are used. Unlike conventional test systems such as microscopes, they are more cost-efficient and work significantly faster. For high-end ceramics substrates, manufacturing tolerances up to 2 µm apply which can be monitored using surfaceCONTROL sensors.

With the surfaceCONTROL 3D 3510 snapshot sensor, fully automated inline inspection of geometry, shape and surfaces of unpopulated PCBs are possible. The sensor achieves best measurement results on matt objects with a repeatability of up to 0.4 µm. The measurement with subsequent calculation and evaluation takes only 1.5 seconds.

Unpopulated PCB substrates serve as basic elements for PCBs that are integrated, for example, into sensors, smartphones and computers. If the evenness of the substrate does not meet the specifications, assemblies cannot be placed exactly during assembly.

The high-precision 3D snapshot sensor surfaceCONTROL 3D 3510 measures directly in the production line on the matt surface of the substrates. The working distance is 120 to 140 mm. The recorded measurement values are calculated in the sensor and output to an external PC via the integrated Gigabit Ethernet interface. Further processing, evaluation and logging of the 3D data is possible with the powerful 3DInspect software (more info).