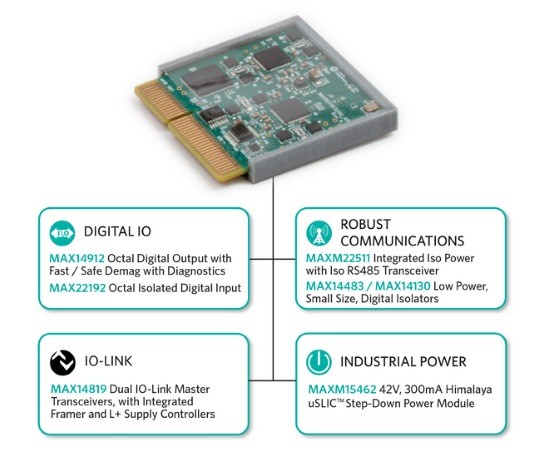

Maxim's Go-IO Drives Intelligence to the Digital Factory Edge

Designers striving to bring greater intelligence into Industry 4.0 digital factory equipment while meeting the stringent size and power demands of the programmable logic controllers (PLCs) inside can now turn to the new Go-IO reference design from Maxim Integrated Products, Inc. Go-IO, which packs 17 configurable IOs in a space one-half the size of a credit card, unleashes the full power of the industrial internet of things (IIoT), enabling productivity-enhancing self-diagnostic capabilities in automated factory subsystems.

Digital factories can dynamically adjust the manufacturing line on the fly based on new or changing requirements. To fully realize industrial convergence, automated equipment must also possess self-diagnostic and optimization capabilities. Go-IO pushes intelligence closer to the edge, enabling active monitoring and communication of equipment health and status information as well as higher throughput and productivity. The reference design also meets increasingly stringent size and power requirements of PLCs, providing a 10x smaller solution with 50 percent less power consumption compared to its industry-leading predecessor, the Pocket IO (more info).