The next revolution in electroless copper for advanced FPCB is now available

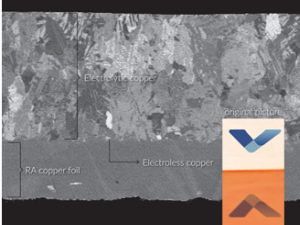

Atotech introduces a new horizontal electroless copper process specifically developed to ensure a blister-free electroless copper deposition and shiny surface appearance after electrolytic copper plating. The new process, Printoganth® RA, is compatible with electro-deposited copper (ED), rolled and annealed (RA) as well as “super-flexible RA” (HA) copper foils and best suited to meet OEM requirements for mobile applications.

RA copper foils are most commonly used for the metallization of next generation flexible substrates. Their special crystal structure, particularly for the “super flexible” HA copper foils, however, requires sophisticated plating solutions in order to achieve the desired surface morphology. One major challenge is the surface appearance after the electrolytic copper plating step. The surface has to have a certain shiny appearance, in order to enable an even etching during structuring and to ensure a reliable automated optical inspection (AOI). In order to overcome this challenge and offer a technically sound solution the Atotech team developed the new Printoganth® RA process that complies with different materials when plating advanced flexible and flex-rigid PCBs.

Phenomenal throwing power meets excellent coverage with good adhesion

Printoganth® RA features an excellent coverage on all relevant base materials, including FR4, PI and PI adhesives. A phenomenal throwing power of more than 70% into blind micro vias (BMV) enables good coverage and thicker electroless copper deposits, also at critical spots such as the BMV corners or on exposed adhesive layers within vias. Due to its favorable internal stress characteristics, Printoganth® RA allows for an excellent and blister free adhesion of the electroless deposited copper layer even on smooth substrates like PI.

Customer verification

“Extensive tests at customer sites have confirmed the outstanding performance of Printoganth® RA,” states Lars-Eric Pribyl, Global Product Manager for desmear and metallization at Atotech Group. “Already today, two leading manufacturers of FPCBs for next generation smartphones are currently using the Atotech process, which is favored by leading smartphone OEMs. It is the combination of higher process safety thanks to higher throwing power and higher yield rates due to the shiny surface after electroplating that convinced them.