Battery-Free, Wireless Sensor Technology Detects Water Leaks During Vehicle Production

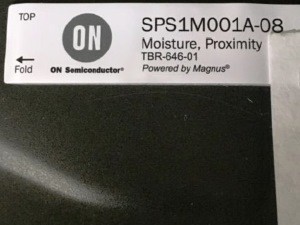

ON Semiconductor and RFMicron have expanded their collaboration to develop a complete in-line vehicle production leak detection solution. The RFM5126 Moisture Intrusion Detection System uses battery-free, wireless sensors to detect in-vehicle water leaks caused by incorrect assembly. Detecting leaks and assembly issues before a vehicle leaves the factory is critical to improving outgoing quality and to avoiding customer warranty issues. The new automated leak detection system, assembled in the production line, enables detection of the smallest damage-inducing leaks.

Vehicle assembly is a complex process involving a range of materials, glues, changing components and human-driven processes. Even with the best traditional efforts, small leaks can go undetected during manual inspection procedures. These leaks may allow enough water into the vehicle over time to cause mold growth and potential damage to expensive electronics modules and components. Statistics show that up to 3% of vehicles ship from the factory with leaks that will lead to mold growth and costly warranty repairs. The RFM5126 Moisture Intrusion Detection System is able to accurately identify these leaks with lower cost and labor impact versus traditional and less effective methods (more info).