Modulation, manipulation, precision: spatial light modulators for industry and research

Due to the increasing miniaturization and complexity in the semiconductor industry, but also in many other technical sectors and industries, high-precision and effective ways of projecting light, processing materials or sending optical signals are required - with precision in the nanometer range and high programming speed at the same time. The spatial light modulators of Fraunhofer IPMS already enable applications in the field of semiconductor technology today, thanks to customized tilting and piston mirror systems. They have the potential to become key components for future applications in material processing, 3D holographic display technology or imaging in biomedicine.

A spatial light modulator consists of several million mirrors on a single semiconductor chip. The tiny mirrors form a micromirror array and, depending on the type of mirror, can be tilted along one or two axes or pulled down individually. This allows them to control and manipulate direction, intensity or phase of light. These spatial light modulators are suitable for a wide range of applications.

1-axis tilting mirrors enable the generation of optical patterns and the structured illumination of surfaces. Gray level pattern projection is applied for microlithography where patterns are transferred into photo resist. Light modulation in the UV and DUV range is a special expertise of Fraunhofer IPMS. Furthermore, 1-axis tilting mirror devices enable a programmable microscope illumination which can be utilized for a non-destructive investigation of sensitive biological samples.

Spatial light modulator micromirror array in ceramic packaging; 512 x 320 individually addressable 2-axis-tilting mirrors with 48 μm pixel size (© Fraunhofer IPMS)

Spatial light modulators can concentrate broad light beams into strong laser spots. The 2-axis tilting mirrors redirect incident light into a large number of beamlets and enable precise control of their directions with minimal loss of light. They are therefore ideal for applications with high light intensities or efficiencies, such as laser ablation or laser engraving.

Piston mirror arrays can generate holographic 3D images in real time. They are promising key components for real holographic 3D head-up displays. The high-precision piston mirror technology also offers potential applications in the field of adaptive optics or optical tweezers.

Spatial light modulator micromirror array with one million individual mirrors (© Fraunhofer IPMS / Sven Döring)

Easy technology transfer and novel concepts for customers

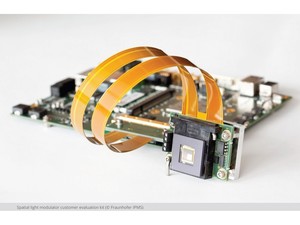

In order to enable technology transfer of the systems into applications, Fraunhofer IPMS offers customer evaluation kits with 64k (256x256) mirrors, which contain either tilting or piston mirror arrays. In addition to the micromirror chip, the Fraunhofer IPMS kit includes control electronics and software. Customer support is offered as well.

About Fraunhofer IPMS

Fraunhofer IPMS is a leading international research and development service provider for electronic and photonic microsystems in the application fields of Smart Industrial Solutions, Bio and Health, Mobility as well as Green and Sustainable Microelectronics. Research focuses on customer-specific miniaturized sensors and actuators, MEMS systems, microdisplays and integrated circuits as well as wireless and wired data communication. The institute develops systems and components on 200 and 300 mm wafers in their state-of-the-art cleanrooms. Services range from consulting and design to process development and pilot series production.